MISCELLANEOUS EQUIPMENT

WHERE EXCELLENCE IS A WAY OF LIFE

BEV undertakes procurement, shop fabrication, assembly, testing, painting and delivery of custom designed static process plant equipment and their components based on OEM design and detailed engineering. Some typical examples of such custom built equipment are:

- Static parts for industrial process compressors, industrial fans

- Furnaces, Hot Air / Gas Generators, Combustors, After Burners,

- Cyclones, Silos

- Chimneys, Stacks, Silencers, Dampers, Ducts

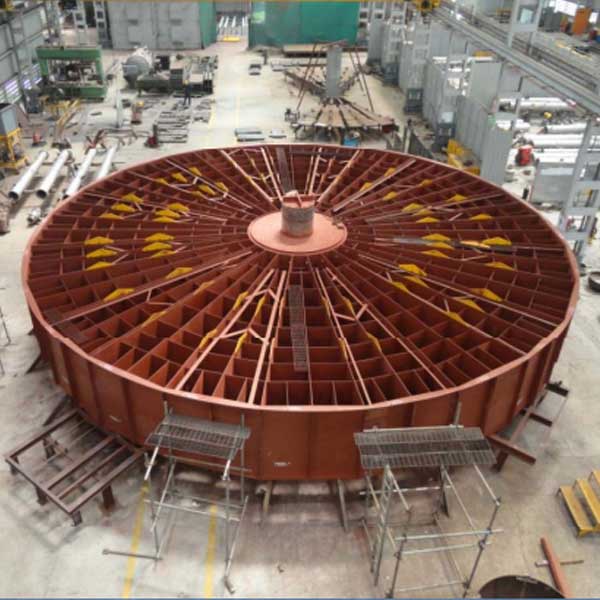

- Rotary Air Preheaters

BEV has already executed or is currently executing projects with several global OEMs such as FLSmidth, Siemens, Jord International, Howden Air & Gas etc. for such products.

BEV has a comprehensive system in place to protect OEM’s intellectual property rights. It comprises of signing a confidentiality and non disclosure agreement, implementing data protection measures at the work place, limiting the information passed on to outside agencies such as subcontractors / service providers strictly on a ‘need-to-know’ basis etc.

- Review design criteria and propose alternative materials, grades / sizes / specifications that are easily available in the local market with a view to optimize the manufacturing costs.

- Review the detailed manufacturing drawings and propose alternative manufacturing, examination and testing practices with a view to optimize the manufacturing costs and / or reducing the lead times

- Develop comprehensive quality control plan, NDE, PWHT, testing procedures and work instructions.

- Review the drawings with a view to improve constructability with resources and infrastructure available locally

- Developing suitable jigs and fixtures to achieve intended tolerances on dimensions

- Review the drawings with a view to optimise packing, handling and transportation arrangements taking into account local conditions

- Propose alternative specifications for welding, welder qualification, NDE etc. with a view to utilise available resources (e.g., ASME Sec IX in lieu of EN281)

BEV has all the machinery and equipment to do shop fabrication and inspection. These are typically,

- CNC Profile Cutter for plasma or oxy gas cutting of components

- Hydraulic Shears, Press Brake and 500 Ton Hydraulic Press for cold shearing and forming

- Semi automatic / CNC band saws for cold cutting of round / square bars, pipes, rolled sections etc.

- SAW, SMAW, GTAW, FCAW welding machines

- GTAW / FCAW with and without oscillator for semi automatic welding

- Machining, drilling

- RT, UT, Dry and wet (fluorescent) MP and DP

- Hydro static testing, pneumatic testing, helium leak testing etc.

- Surface preparation using grit and shot blasting, coating / painting Assembly, Factory Acceptance Testing (with or without power and utilities)

Materials of construction range from carbon steel, alloy steel through stainless steel including exotic metals like SMO (6% Mo) and Duplex/Super Duplex Stainless Steel. We have an extensive range of WPQRs covering a wide range of materials, thicknesses and welding processes such as SAW, SMAW, GTAW and FCAW. If welders and welding operators are required to be certified by recognised third party certification agencies, it could be arranged with Bureau Veritas or TUV. We have a wide range of welding manipulators such as column and boom 4 M x 7 M, heavy duty rotators up to 100 tons and positioners up to 3 tons.

We have a well equipped machine shop with a with a 3 Axis CNC Vertical Machining Centre Hartford PRO 3210 imported from Taiwan with bed size 3150 mm x 2100 mm with 70 bar through coolant BT50, 6000 rpm spindle, 20 tools ATC, right angle milling head and Fanuc controller. The machine shop also has a radial drill and 3 gap bed lathes. Exotic metals are handled using stringent material control and handling procedures and work is carried out in controlled environment. We carry out post weld heat treatment / stress relieving in temporary purpose built temporary furnaces within our facility or in gas fired furnaces at a specialist subcontractor’s premises.

We have a totally enclosed steel grit blasting facility complying with Euro III norms imported from Hodge Clemco, UK. Its size is 16M (L) x 8 M (W) x 5 M (H). Items bigger than this are blasted under custom built canopies using 200 litres blast pots and copper slag as abrasive medium. Painting facility is fully equipped with air less spray painting machine as well as cup guns. Special erosion resistant internal coatings can be applied using Belzona or Ceramkote products. If rubber / PTFE / PPE lining is required, these could be arranged through specialist subcontractors.

Equipment can be supplied with ‘CE’ marking, GOST-R or GOST-K certification. If independent third party certification or stage wise inspection is required for the product, it could be arranged through reputed agencies such as Bureau Veritas, TUV Nord, Lloyds Register, American Bureau of Shipping, DNV, SGS etc.

Management team has extensive experience in the heavy engineering industry within and outside India, especially with multi national companies, EPC global contractors, service providers etc. We have competent QC Inspectors, AWS/CSWIP 3.1/3.2 Certified Welding Inspectors, API 510 Pressure Vessel Inspectors and BGAS Grade II Painting Inspectors. In short, you are assured of a truly world class service within India. For a list of pressure vessel projects recently executed / in progress, click here.

Our Certifications

WHERE EXCELLENCE IS A WAY OF LIFE