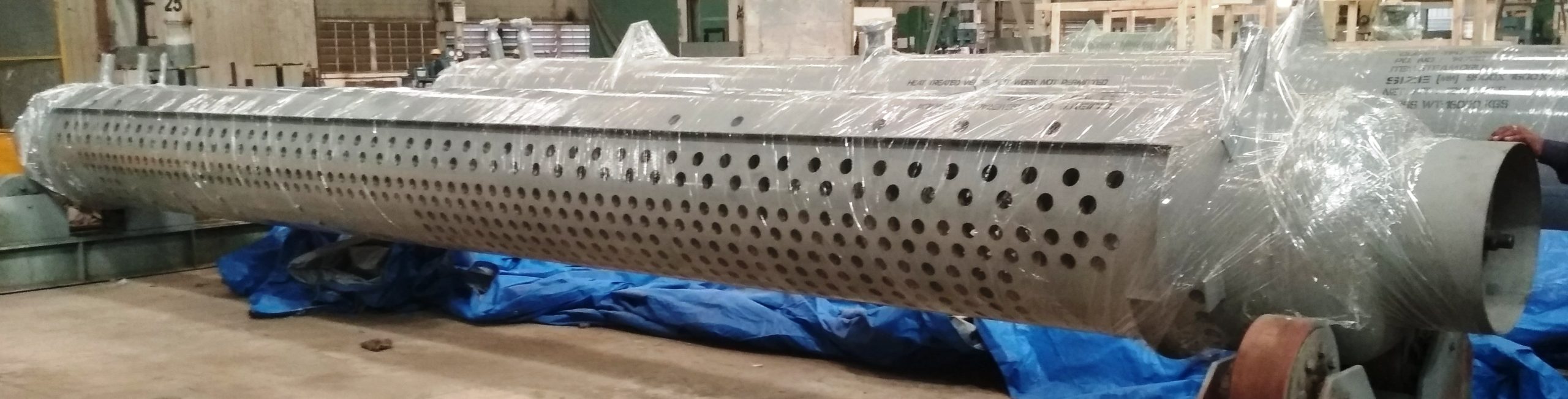

Tube bundles: 38.1 x 3.2 and 25.4 x 3.2 mm SS 304 incl R/D 1.0 bends; 8 tube bundles. Weight 5.5 MT each

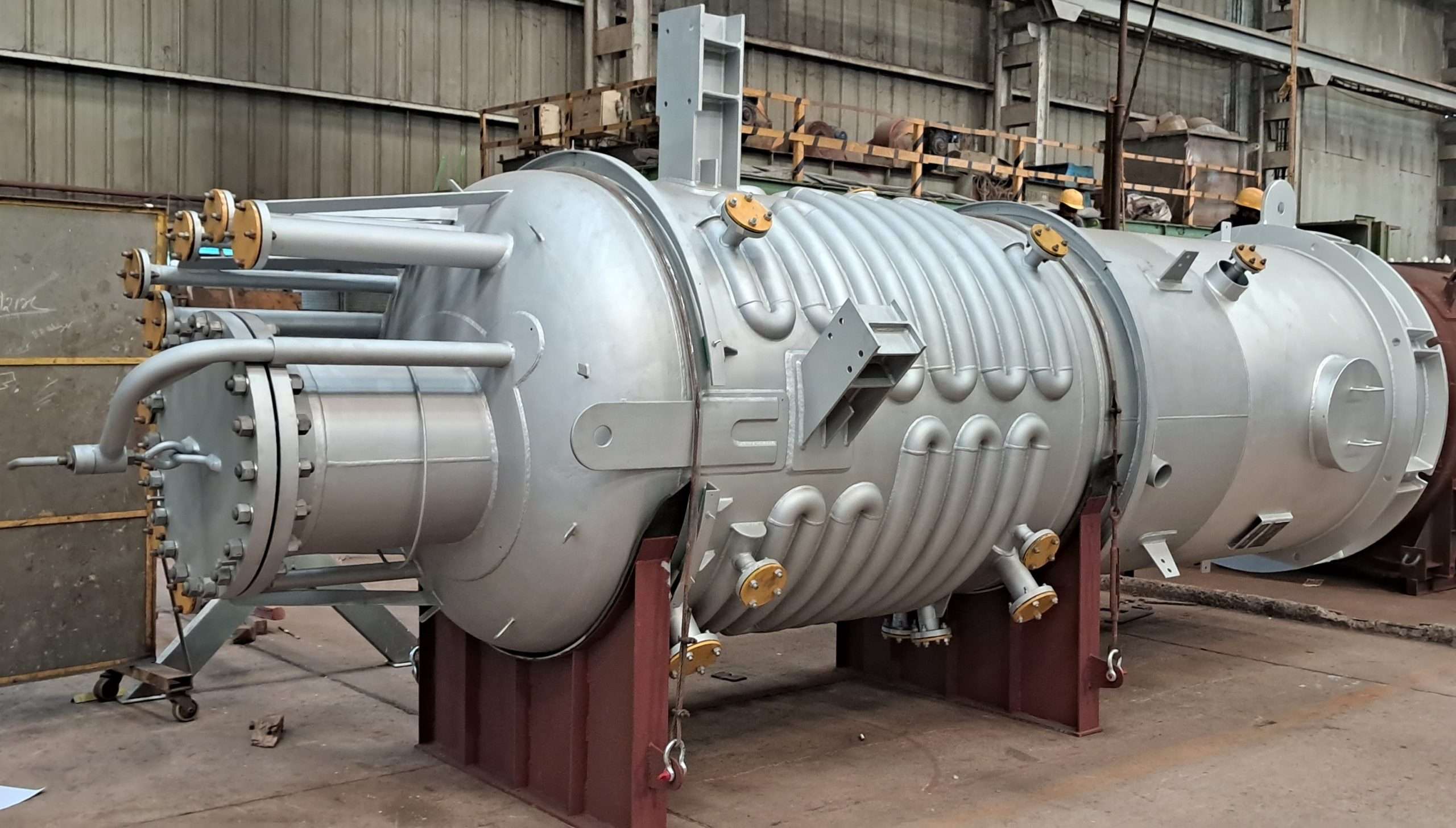

Internal 3 concentric coils of 3” Sch 160 Alloy 20 (UNS N08020) arranged in 2 rows with 6” Sch 160 forged header with extruded stubs, all supports in Alloy 20. FEA of coil manifold done.

Aluminum Alkyls Reactor:

Design Pressure: 84 bar (shell), 14 bar (internal coils)

Design Temperature: 370 degC

Medium: Aluminum Alkyls

Weight: 54.3 MT

Working Volume: 25 CuM

ID: 2896 mm Thk: 116 mm (shell), 53.5 mm (Hemispherical D/E), SA 516 Gr 70

Length T/T: 1871 mm, O/A: 5921 mm

Temperature Swing Molecular Sieve Adsorber for Air Products, Netherlands for Gasunie Project, Zuidbroek, Netherlands. 5.86 M ID x 38 mm thk, 72.8 MT each x 6 No. to EN13445 and PED 2014/68/EU

Propylene Refrigerant Receiver. 4.6 M ID x 40 mm thk x 13.8 M T/T, 16.56 M O/A, SA 516 Gr 70, Wt 91.4 MT

Refrigerant Suction Drum. 3.8 M ID x 22.15 M (T/T) x 37.45 M Overall Length, SA 516 Gr 60, Wt 128.5 MT.

Spent Caustic Deoiling Drum: 2.8 M ID x 36 mm thk x 8.2 M T/T, 10.6 M O/A, SA 516 Gr 60, Weight 36.2 MT

Dryer Feed KO Drum: 3.9 M ID x 44 mm thk x 6.9 M T/T, 14.36 M O/A, SA 516 Gr 70, Weight 69.6 MT, Gross Weight 73.7 MT

PreDistillation Inhibitor Drum: 1.3 M ID x 6 mm thk x 1.4 M T/T, 5 M O/A, SA 240 Gr 304L, Wt 2.15 MT

Cold Box H: 12.5 M (L) x 3.7 M (W) x 4 M (H), 21.7 MT weight comprising 3 SS 304 Drums, 663 Dia Inch SS304 Pipe Work and Structural Frame

Cold Box E: 13.4 M (L) x 5 M (W) x 4.2 M (H), 30.5 MT weight comprising 3 SS 304 Drums, 781 Dia Inch SS304 Pipe Work and Structural Frame

Cold Box D: 13 M (L) x 4 M (W) x 4 M (H), 31.0 MT weight comprising 2 SS 304 Drums, 584 Dia Inch SS304 Pipe Work and Structural Frame

Cold Box B: 10.4 M (L) x 5.6 M (W) x 4.5 M (H), 38.5 MT weight comprising 1 SS 304 Drum, 755 Dia Inch SS304 Pipe Work and Structural Frame

Cold Box A: 7 M (L) x 3.4 M (W) x 3.0 M (H), 8.5 MT weight comprising 1 SS 304 Drum, 230 Dia Inch SS304 Pipe Work and Structural Frame

Cold Box K: 6.9 M (L) x 3.4 M (W) x 3.6 M (H), 14.0 MT weight comprising 1 SS 304 Drum, 359 Dia Inch SS304 Pipe Work and Structural Frame

Cold Box I: 10.9 M (L) x 4.2 M (W) x 4.0 M (H), 27.3 MT weight comprising 4 SS 304 Drums, 956 Dia Inch SS304 Pipe Work and Structural Frame

Cold Box J: 8.9 M (L) x 4.7 M (W) x 4.2 M (H), 26.4 MT weight comprising 2 SS 304 Drums, 690 Dia Inch SS304 Pipe Work and Structural Frame

Second Stage HDS Finishing Reactor in Low Alloy Steel (SA387 Gr 11 Cl 2) cladded with SS321, OD 2.462 M x 28+3 mm thk x 5.8 M T/T 12.6 M O/A, Wt 29.3 MT